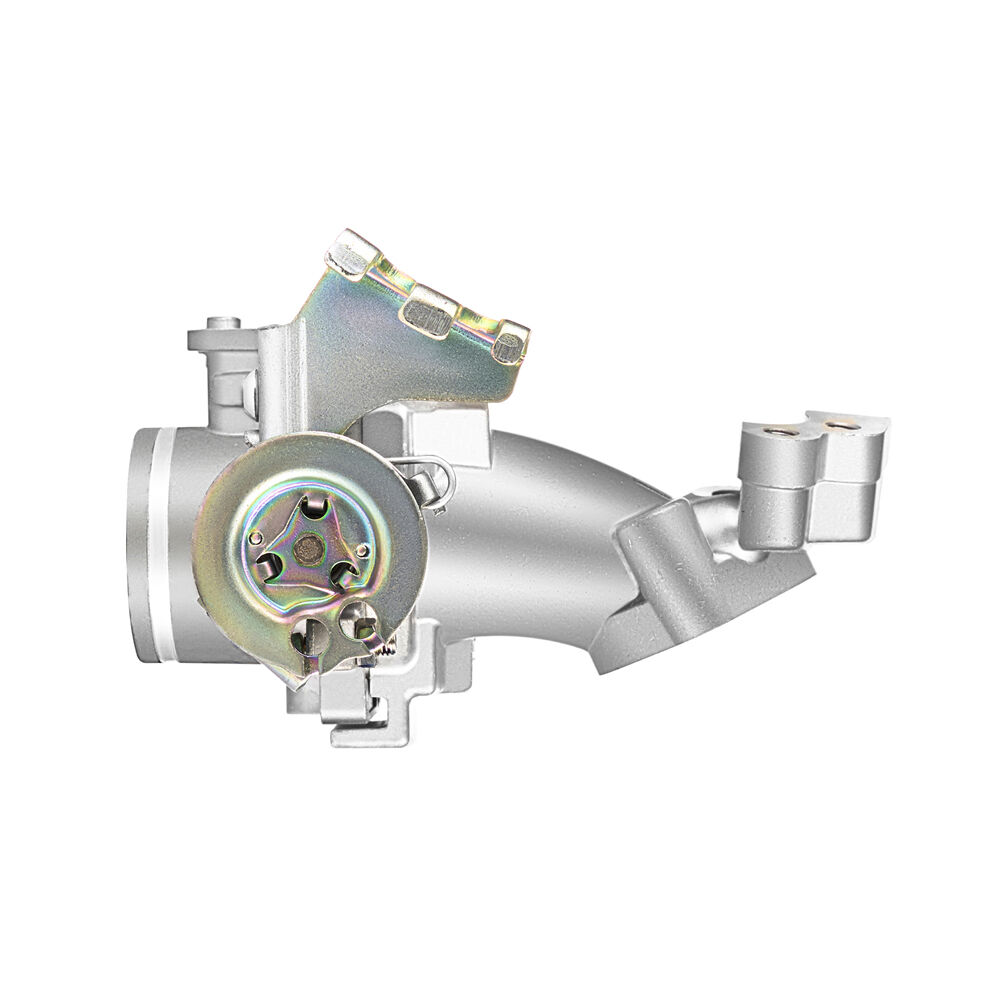

carburetor rebuild kit for small engines

A carburetor rebuild kit for small engines represents an essential maintenance solution designed to restore and optimize the performance of various small engine carburetors. These comprehensive kits typically include all necessary components such as gaskets, O-rings, float needles, metering jets, and adjustment screws required for a complete carburetor overhaul. The kit's primary function is to replace worn or damaged parts that affect fuel delivery and air mixture, ensuring optimal engine performance. Modern rebuild kits are engineered with high-quality materials that meet or exceed OEM specifications, providing enhanced durability and reliability. These kits are compatible with a wide range of small engines found in lawn mowers, generators, pressure washers, and other outdoor power equipment. The precision-manufactured components ensure proper fuel atomization and mixture control, leading to improved engine starting, smoother operation, and increased fuel efficiency. The kits often feature updated designs that address common issues found in original carburetors, incorporating improvements in material quality and component design for better long-term performance.