map sensor connector types

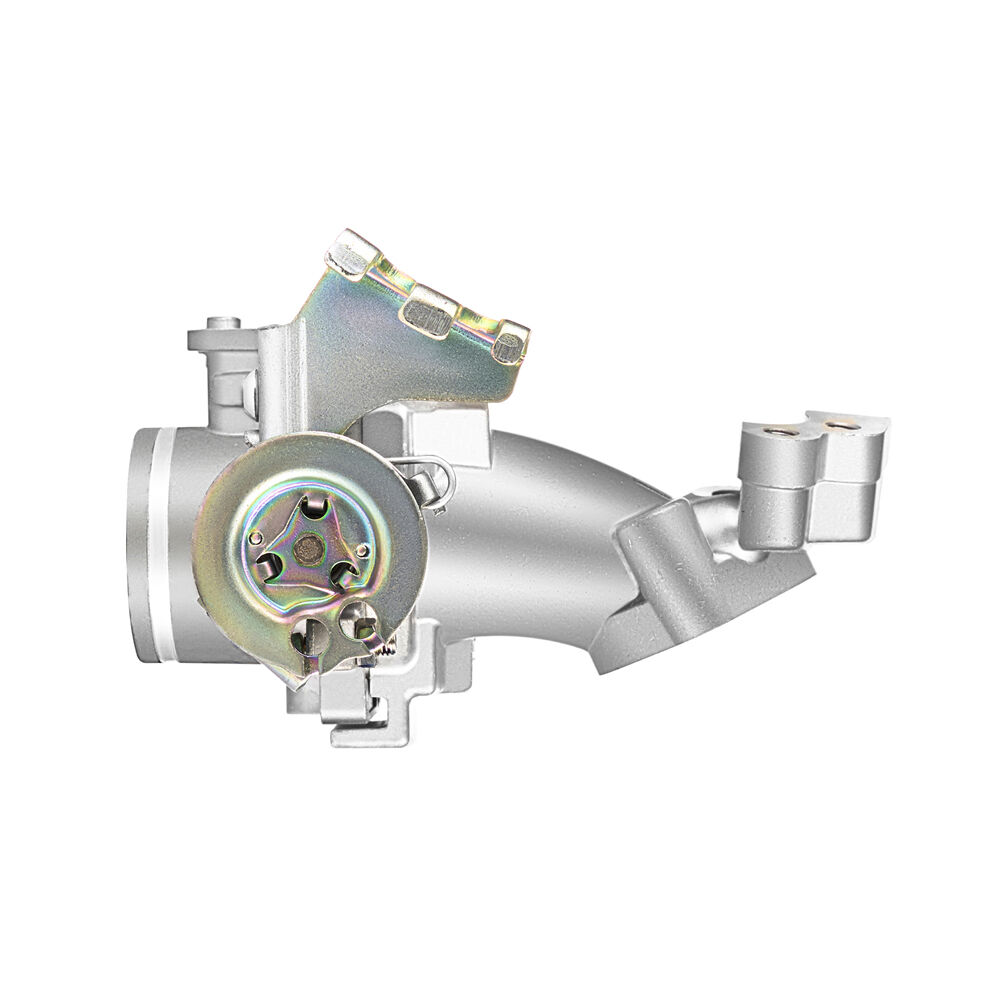

Map sensor connector types play a crucial role in modern automotive systems, serving as vital components that ensure accurate measurement of manifold absolute pressure. These connectors come in various configurations, including weatherpack, metri-pack, and standard pin-type connections, each designed to maintain reliable electrical connections in demanding environments. The connectors feature specialized sealing mechanisms that protect against moisture, dust, and other contaminants, ensuring consistent sensor performance across varying operating conditions. Modern map sensor connectors incorporate advanced materials like high-grade thermoplastics and corrosion-resistant metals, providing excellent durability and longevity. They are engineered with precise pin alignment and robust locking mechanisms to prevent accidental disconnection during vehicle operation. The design typically includes between 3 to 4 pins that transmit power, ground, and signal data between the sensor and the engine control unit. These connectors are compatible with both analog and digital map sensors, supporting various communication protocols used in modern engine management systems.