Understanding the Critical Role of Throttle Bodies in Motorcycle Performance

At the heart of every modern motorcycle's fuel delivery system lies the motorcycle throttle body, a precision-engineered component that significantly influences how your bike responds to throttle inputs. This sophisticated device acts as the gateway between the air intake system and the engine, carefully managing the air-fuel mixture that powers your motorcycle. Whether you're a seasoned rider seeking better performance or a motorcycle enthusiast looking to understand your bike's mechanics, grasping how the throttle body functions is essential for optimizing your riding experience.

The motorcycle throttle body represents a remarkable evolution in fuel delivery technology, replacing traditional carburetors in most modern bikes. This transition has brought unprecedented levels of precision, efficiency, and control to motorcycle operation. By electronically controlling the air-fuel mixture, the throttle body system ensures optimal performance across various riding conditions, from idle to full throttle.

Components and Functionality of Modern Throttle Bodies

Essential Parts of a Throttle Body System

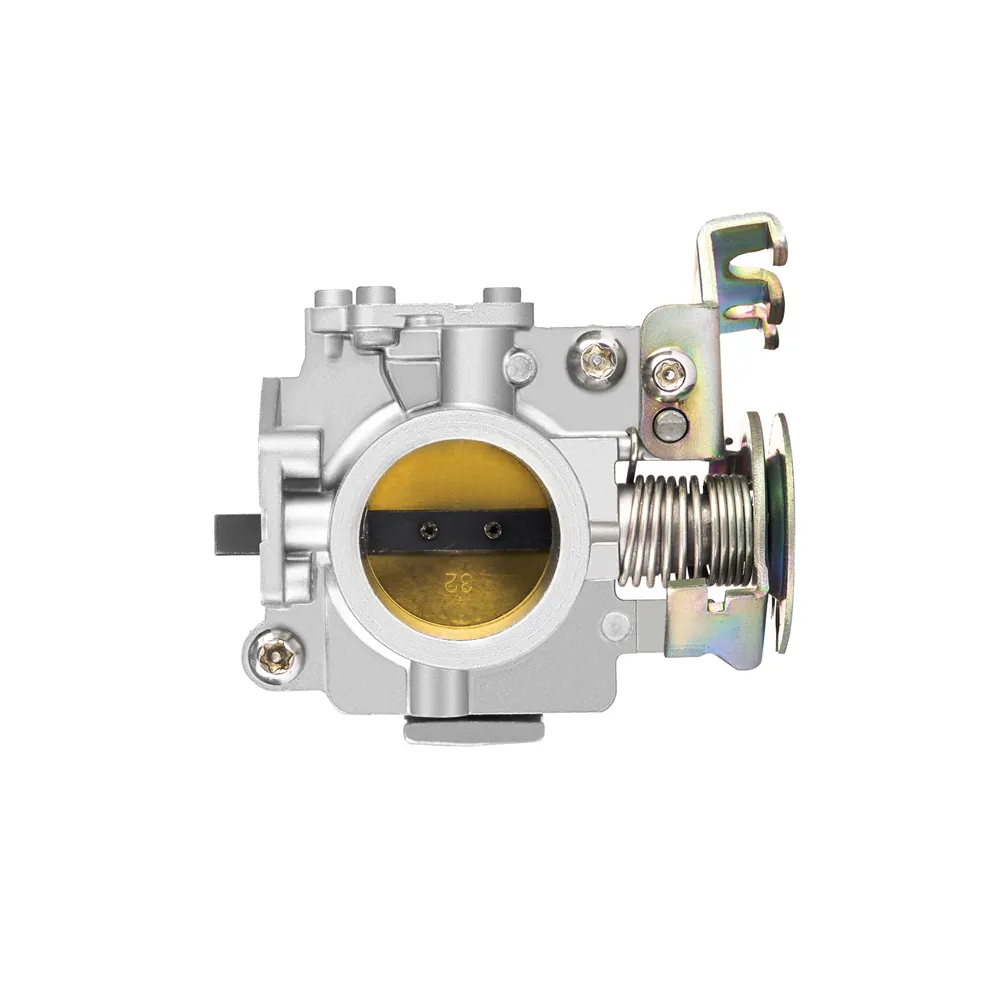

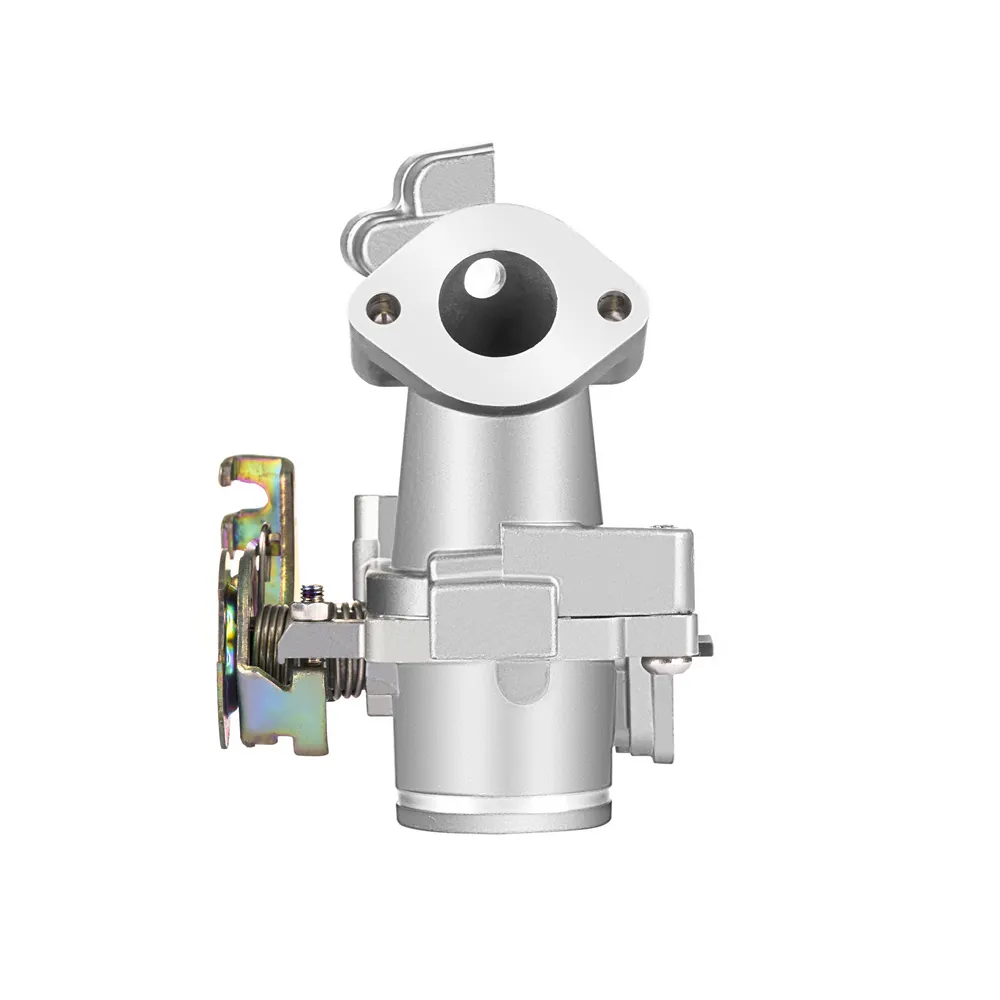

The motorcycle throttle body consists of several crucial components working in harmony. The butterfly valve, controlled by the rider's throttle input, regulates airflow into the engine. The throttle position sensor (TPS) monitors the valve's position, while the idle air control valve maintains stable engine speed when stationary. Fuel injectors, precisely calibrated for optimal fuel delivery, complete this sophisticated system.

Electronic control units (ECU) work alongside these components, processing data from various sensors to adjust fuel delivery in real-time. This intricate network ensures the perfect air-fuel ratio regardless of environmental conditions or riding demands, something traditional carburetors could never achieve with such precision.

Advanced Sensor Integration

Modern motorcycle throttle body systems incorporate multiple sensors that continuously monitor operating conditions. These include air temperature sensors, manifold absolute pressure sensors, and oxygen sensors. This comprehensive data collection enables the system to make split-second adjustments, ensuring optimal performance and efficiency at all times.

The integration of these sensors represents a significant advancement in motorcycle technology, allowing for unprecedented levels of control and responsiveness. Each sensor provides vital information that helps the ECU fine-tune the fuel delivery system, resulting in improved power delivery and reduced emissions.

Performance Benefits and Riding Experience

Enhanced Power Delivery

The precise control offered by a motorcycle throttle body system translates directly into superior power delivery. Riders experience smoother acceleration, better throttle response, and more consistent performance across the entire RPM range. This improved control allows for more confident riding, whether navigating tight city streets or opening up the throttle on open highways.

The system's ability to adapt to changing conditions means that power is always available when needed, without the hesitation or lag often associated with traditional carburetor systems. This responsiveness is particularly noticeable during quick acceleration or when maintaining steady speeds in varying conditions.

Fuel Efficiency Improvements

Modern motorcycle throttle body systems excel at optimizing fuel consumption. By precisely metering fuel delivery based on real-time engine demands, these systems achieve significantly better fuel efficiency compared to carbureted engines. This improvement doesn't just mean fewer stops at the gas station; it also translates to reduced emissions and lower operating costs.

The system's ability to maintain optimal air-fuel ratios across different operating conditions ensures that every drop of fuel is used effectively. This efficiency is particularly noticeable during steady-state cruising, where the throttle body can maintain lean fuel mixtures without compromising performance.

Maintenance and Optimization

Regular Service Requirements

Maintaining a motorcycle throttle body system requires attention to detail and regular service intervals. Clean fuel and air filters are essential for optimal performance, as contaminants can affect sensor readings and fuel delivery accuracy. Regular inspection of throttle body components, including the butterfly valve and sensors, helps ensure continued optimal performance.

Professional cleaning services can remove carbon deposits and other contaminants that may accumulate over time. This maintenance is crucial for preserving the precise control and efficiency that make throttle body systems superior to traditional carburetors.

Performance Tuning Opportunities

The electronic nature of motorcycle throttle body systems opens up numerous possibilities for performance tuning. Through ECU mapping and careful adjustment of fuel delivery parameters, riders can optimize their bikes for specific riding conditions or performance goals. However, these modifications should be approached with caution and preferably handled by qualified professionals.

Advanced diagnostic tools can help identify potential issues and optimize system performance. Modern scanning tools can read sensor data in real-time, allowing for precise adjustments that maximize both performance and efficiency.

Future Developments and Trends

Integration with Smart Technology

The evolution of motorcycle throttle body technology continues with the integration of smart features and connectivity options. Future systems may incorporate machine learning algorithms to better predict and adapt to rider preferences and changing conditions. This could lead to even more responsive and personalized riding experiences.

Wireless connectivity might allow for remote diagnostics and tuning, while smartphone integration could provide riders with real-time performance data and maintenance alerts. These advancements promise to make motorcycle operation even more efficient and user-friendly.

Environmental Considerations

As environmental regulations become stricter, motorcycle throttle body systems will play an increasingly important role in emissions control. Manufacturers are developing more sophisticated systems that can maintain performance while meeting these stringent requirements. This includes advanced fuel mapping strategies and improved sensor technology for more precise control over emissions.

The trend toward cleaner motorcycle operation will likely drive further innovations in throttle body design and functionality. This could include integration with hybrid powertrains or adaptation for alternative fuels, ensuring that motorcycles remain both exciting to ride and environmentally responsible.

Frequently Asked Questions

How often should a motorcycle throttle body be serviced?

A motorcycle throttle body should typically be inspected and serviced every 12,000 to 15,000 miles, or annually, whichever comes first. However, this interval may vary depending on riding conditions and manufacturer recommendations. Regular maintenance ensures optimal performance and longevity of the system.

Can a throttle body be cleaned without removing it?

While basic cleaning can be performed without removal using specialized throttle body cleaning sprays, a thorough cleaning usually requires removing the throttle body from the motorcycle. This allows for proper inspection and cleaning of all components, ensuring the best possible performance.

What are the signs of a failing throttle body?

Common symptoms of throttle body issues include irregular idle speed, poor throttle response, decreased fuel efficiency, and check engine light illumination. You might also notice hesitation during acceleration or rough running conditions. If these symptoms occur, professional inspection is recommended.