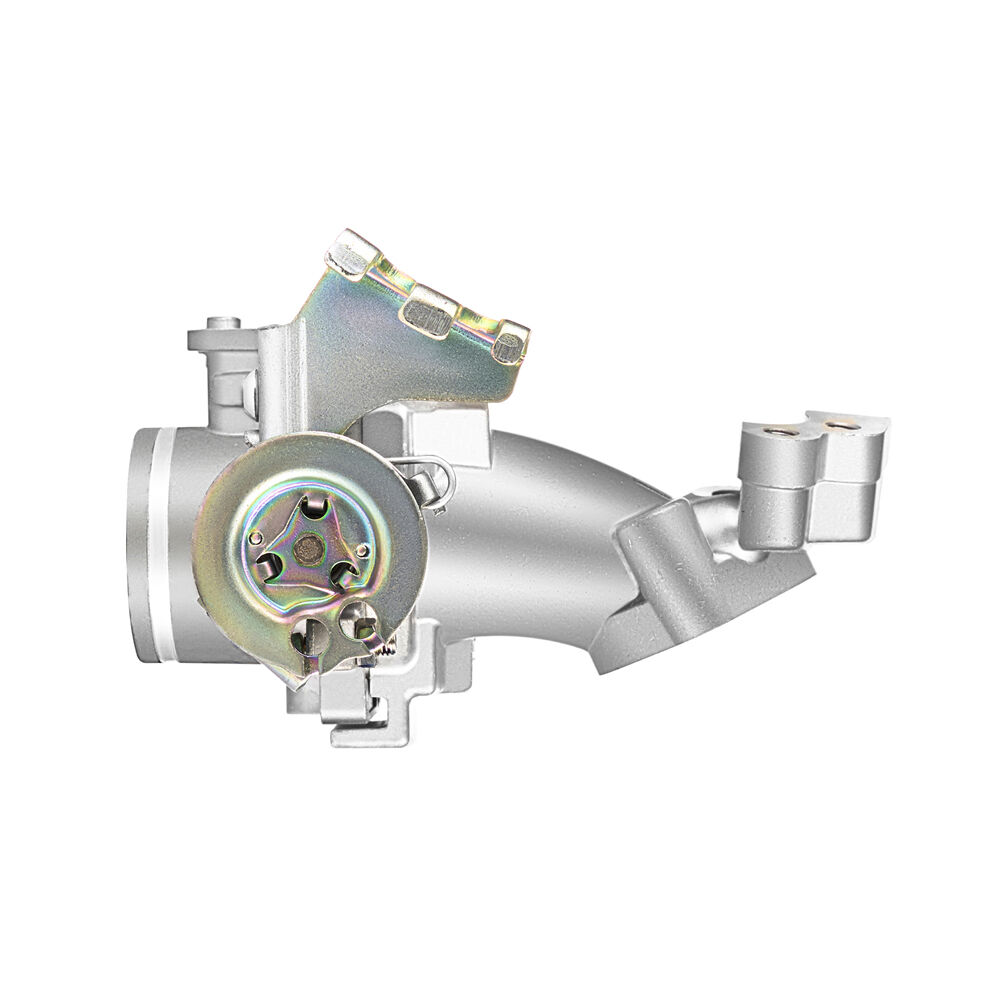

air intake pressure sensor

The air intake pressure sensor is a critical component in modern engine management systems, serving as a vital instrument for monitoring and optimizing engine performance. This sophisticated device measures the absolute pressure within the intake manifold, providing real-time data that helps the engine control unit (ECU) make precise adjustments to fuel delivery and ignition timing. Operating through advanced piezoelectric or capacitive sensing technology, the sensor converts pressure variations into electrical signals that the ECU can interpret. The sensor's primary function involves detecting changes in manifold absolute pressure (MAP), which directly correlates to engine load and atmospheric conditions. In turbocharged applications, it plays an additional role in monitoring boost pressure to prevent engine damage. The sensor's accuracy is crucial for maintaining optimal air-fuel ratios across various operating conditions, from idle to full throttle. Its robust construction ensures reliable operation in harsh underhood environments, while its rapid response time enables split-second adjustments to engine parameters. This technology has become increasingly important in meeting stringent emissions regulations while maximizing engine efficiency and performance. The sensor's integration with modern engine management systems allows for adaptive learning capabilities, ensuring consistent performance throughout the engine's lifetime.