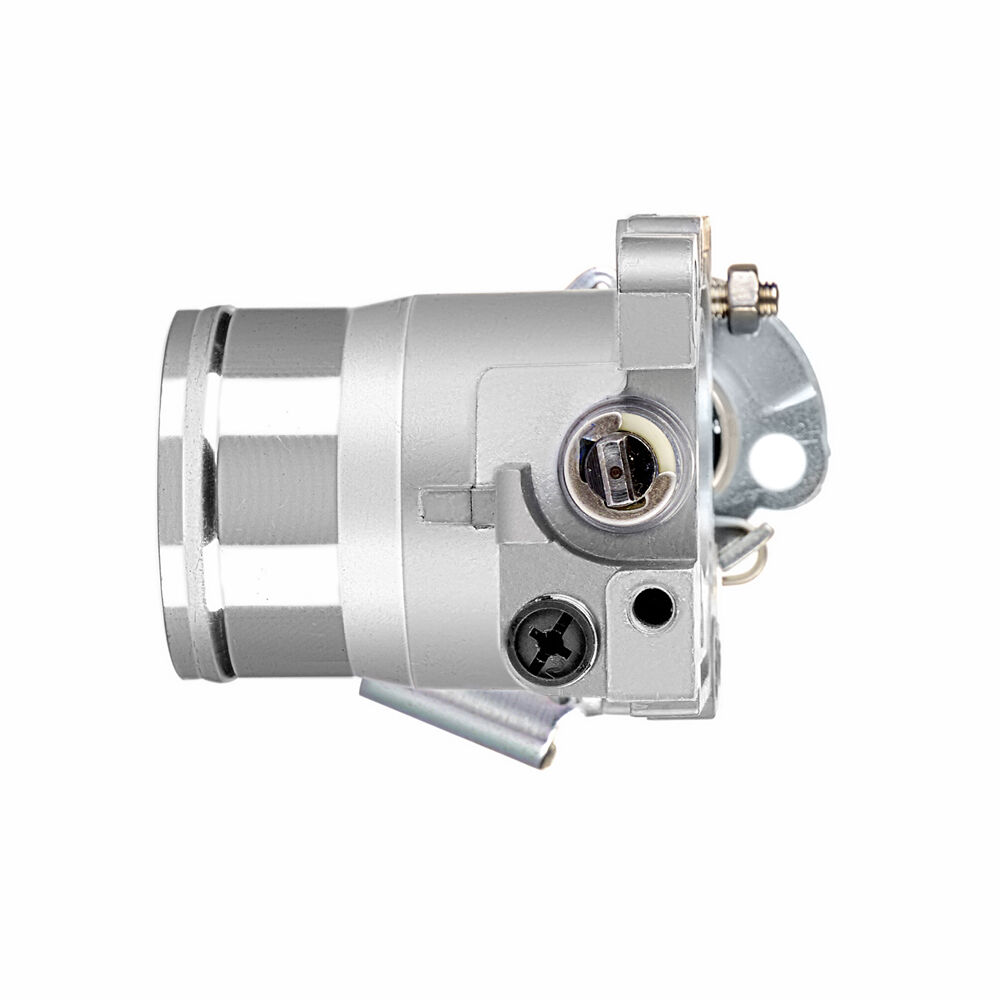

engine crankshaft sensor

The engine crankshaft sensor is a crucial component in modern vehicle engines, serving as a vital monitoring device that precisely tracks the position and rotational speed of the crankshaft. This sophisticated sensor employs electromagnetic technology to generate signals that are essential for proper engine timing and performance. Located near the engine's crankshaft, it continuously monitors the position of timing marks on the crankshaft and transmits this data to the engine control unit (ECU). The sensor's primary function is to determine the exact position of the engine's pistons, enabling optimal fuel injection timing and ignition system operation. By providing real-time data about crankshaft position and speed, it helps maintain proper engine timing, ensures efficient fuel consumption, and supports smooth engine operation. The sensor's design typically incorporates durable materials and advanced sensing elements to withstand harsh engine environments, including extreme temperatures and vibrations. Its reliability is paramount as it plays a fundamental role in engine management, affecting everything from start-up performance to fuel efficiency and emissions control. Modern crankshaft sensors often feature enhanced electromagnetic shielding to prevent interference from other electrical systems, ensuring accurate and consistent readings under all operating conditions.