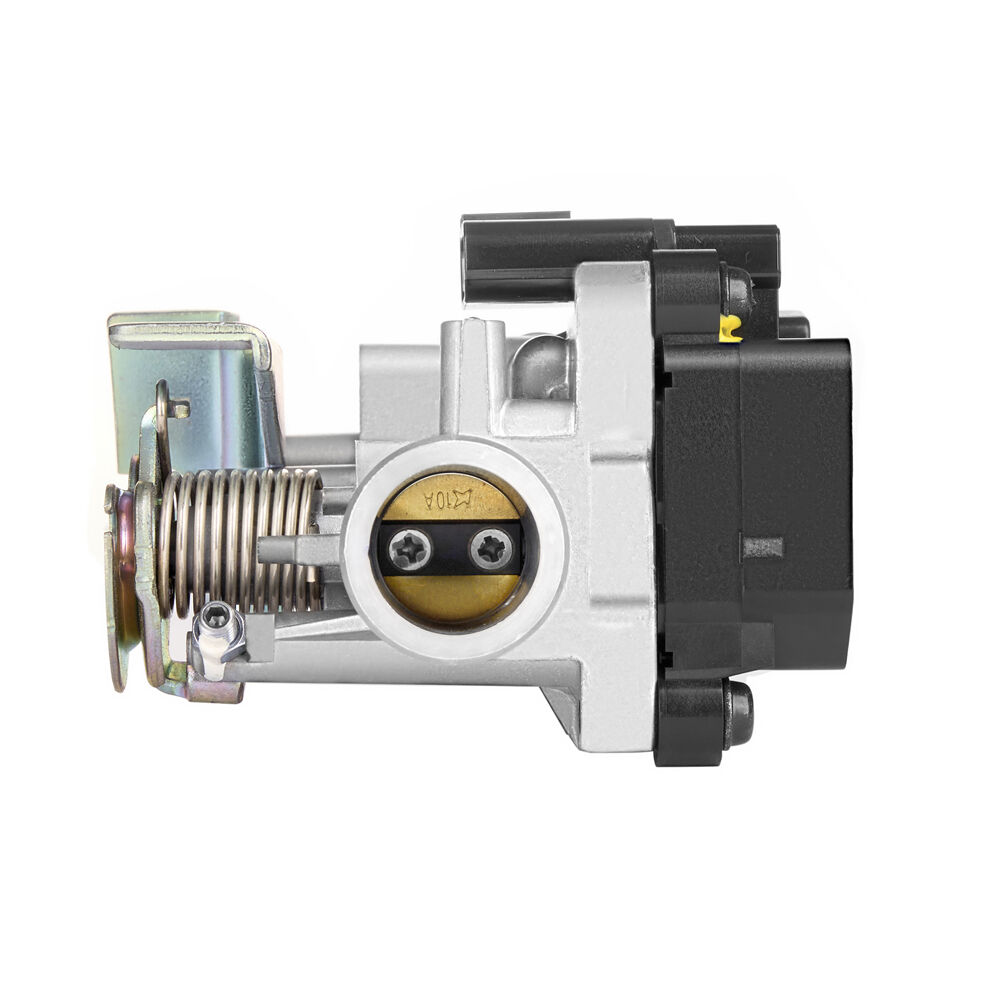

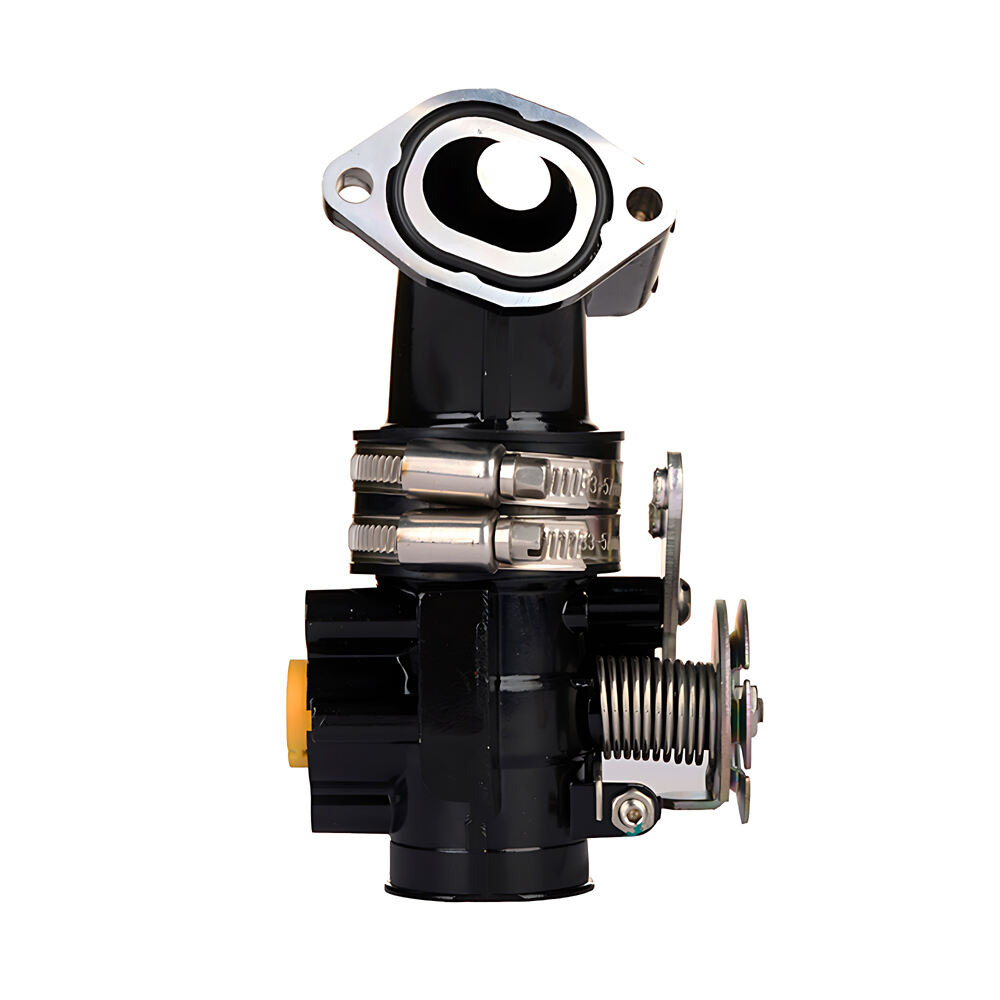

motorcycle crankshaft sensor

The motorcycle crankshaft sensor is a vital electronic component that plays a crucial role in modern motorcycle engine management systems. This precision instrument monitors the position and rotational speed of the crankshaft, providing essential data to the engine control unit (ECU) for optimal engine performance. The sensor utilizes electromagnetic technology to generate precise signals as the crankshaft rotates, enabling accurate timing of fuel injection and ignition systems. Located near the crankshaft, typically mounted on the engine block, this sensor continuously tracks the position of the crankshaft through a toothed wheel or reluctor ring. By detecting these magnetic variations, the sensor transmits real-time data that helps maintain proper engine timing, fuel efficiency, and overall performance. The technology employs either a Hall effect or magnetic reluctance design, both offering reliable performance across various operating conditions. Modern motorcycle crankshaft sensors are built to withstand extreme temperatures, vibrations, and harsh environmental conditions, ensuring consistent operation throughout the motorcycle's lifetime. This component has become increasingly sophisticated with advancing technology, now capable of providing more accurate readings and better resistance to electromagnetic interference.