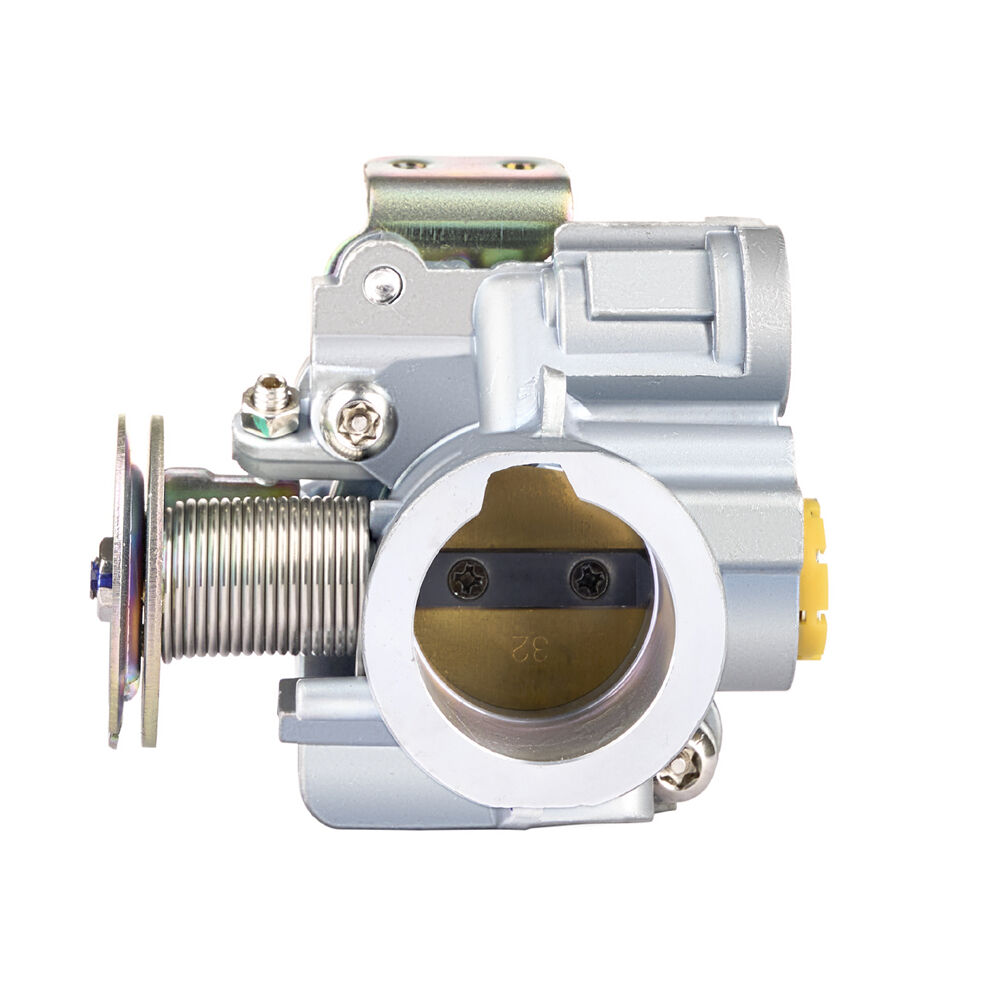

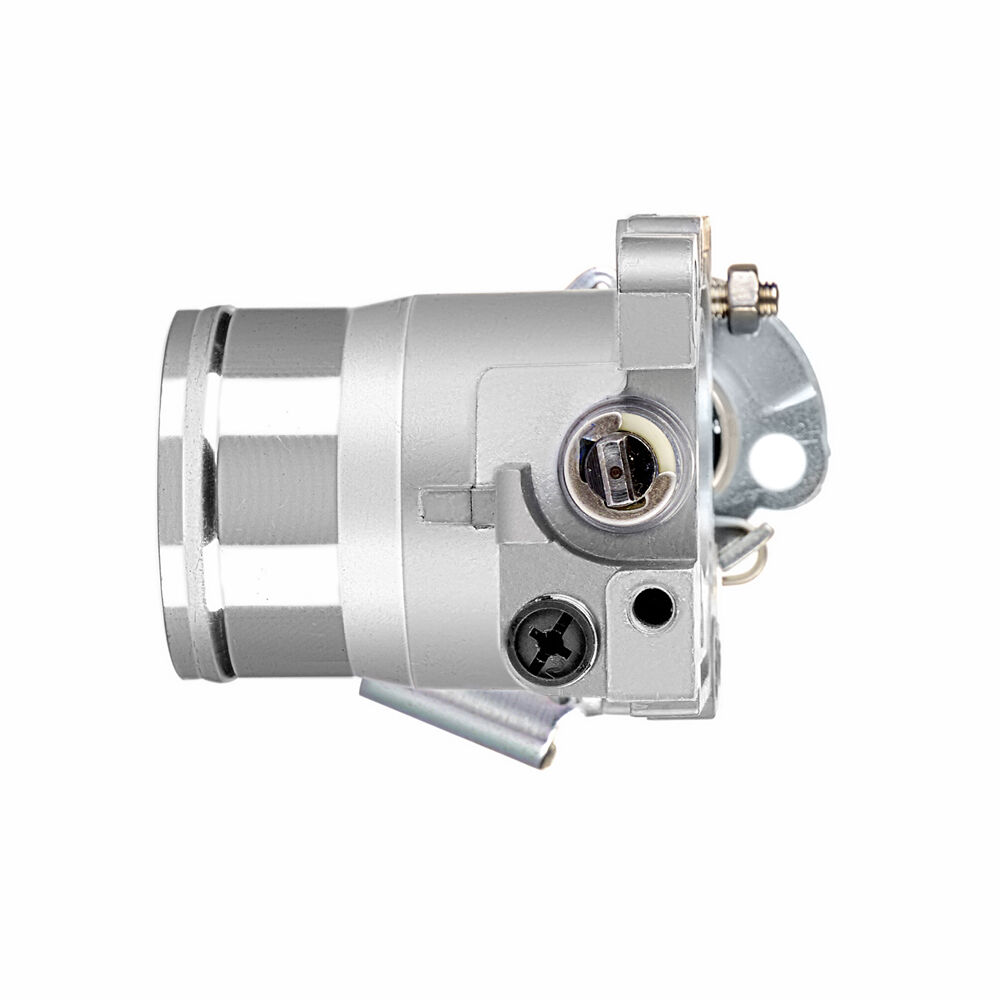

дроселна клапа за представяне

Тротилната клапа за представяне е критичен компонент в съвременните системи на двигатели на превозни средства и служи като основен вход за контрол на въздушния поток към впускателния колектор на двигателя. Това прецизно изработено устройство се състои от клапа тип пеперудка, разположена в специално проектирана цилиндрична част, която отговаря на входните сигнали от педала на газта, за да регулира количеството въздух, постъпващ в камерата на горене. Напредналите тротилни клапи за представяне разполагат с по-големи отвори в сравнение със стандартните единици, обикновено в диапазона от 65 мм до 102 мм, което позволява увеличен въздушен поток. Тези устройства често включват сложни електронни сензори и актуатори, които работят в синхрон с управляващия блок на двигателя (ECU), за да се оптимизира съотношението на въздух-гориво. Изработени са от висококачествени алуминиеви материали с прецизно обработени повърхности, за да се осигури минимално съпротивление на въздуха и максимална ефективност на потока. Съвременните тротилни клапи за представяне също разполагат с интегрирани системи за контрол на холостия ход и сензори за позицията на тротила, осигурявайки прецизен контрол върху представянето на двигателя при всички работни условия. Този компонент е съществен както при атмосферни, така и при двигатели с принудително захранване, предлагайки подобрена чувствителност на тротила и увеличена мощност в целия диапазон на оборотите.