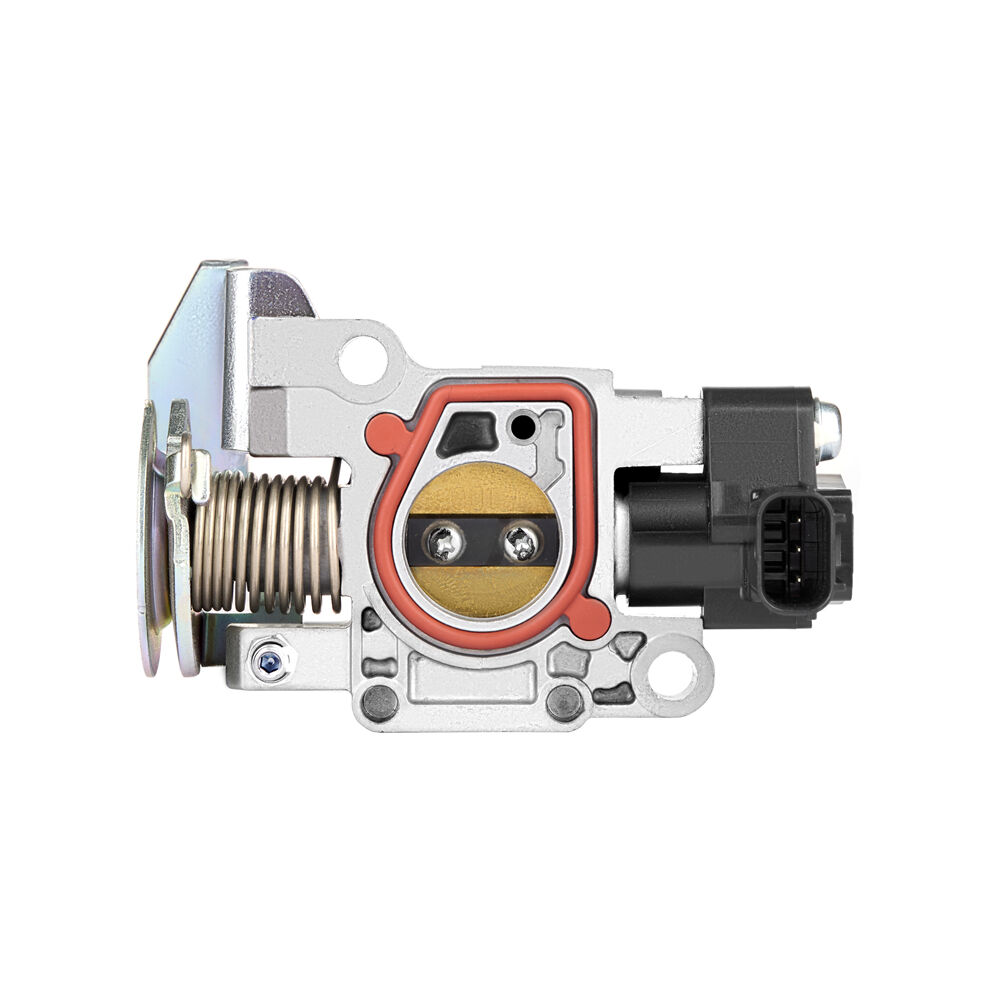

map sensor on the market

A MAP (Manifold Absolute Pressure) sensor is a critical component in modern engine management systems, designed to optimize engine performance and fuel efficiency. This sophisticated device measures the absolute pressure inside the engine's intake manifold, providing essential data to the engine control unit (ECU). Modern MAP sensors utilize advanced piezoresistive technology, which enables them to deliver highly accurate pressure readings across various operating conditions. The sensor's primary function involves monitoring air density and load on the engine, allowing for precise fuel injection timing and quantity adjustments. In the current market, MAP sensors come in various configurations to suit different vehicle applications, from standard automotive use to high-performance racing applications. These sensors typically operate within a pressure range of 0 to 250 kPa, offering exceptional accuracy typically within 1% of the full scale. The technology has evolved significantly, with many contemporary MAP sensors incorporating temperature sensing capabilities for enhanced precision. They play a vital role in maintaining optimal air-fuel ratios, ensuring efficient combustion, and helping vehicles meet increasingly stringent emissions standards. The market offers both OEM and aftermarket options, with various price points and quality levels to meet different consumer needs and vehicle specifications.