Understanding how a motorcycle carburetor functions is essential for any rider who wants to optimize their bike's performance and maintain reliable operation. The motorcycle carburetor serves as the heart of the fuel delivery system, precisely mixing air and fuel to create the combustible mixture that powers your engine. This intricate mechanical device has been the backbone of motorcycle engines for decades, and despite the rise of fuel injection systems, carburetors remain widely used in many motorcycle applications due to their simplicity, reliability, and ease of maintenance.

Fundamental Principles of Carburetor Operation

Venturi Effect and Air-Fuel Mixing

The motorcycle carburetor operates on the fundamental principle of the Venturi effect, which creates a pressure differential that draws fuel into the airstream. As air flows through the carburetor's narrow throat, called the venturi, its velocity increases while pressure decreases. This pressure drop creates suction that pulls fuel from the float bowl through precisely calibrated jets and passages, mixing it with the incoming air to form the proper air-fuel ratio for combustion.

The effectiveness of this mixing process depends on several critical factors including air velocity, fuel viscosity, and the geometric design of the carburetor body. Modern motorcycle carburetors utilize sophisticated engineering to ensure consistent fuel atomization across varying engine speeds and loads. The atomized fuel particles must be small enough to vaporize quickly and mix uniformly with the air, creating an optimal combustible mixture that burns efficiently in the engine's combustion chamber.

Atmospheric Pressure and Fuel Delivery

Atmospheric pressure plays a crucial role in carburetor operation, as it provides the driving force that pushes fuel from the float bowl into the venturi. Changes in altitude, temperature, and barometric pressure can significantly affect carburetor performance, requiring adjustments to maintain optimal air-fuel ratios. At higher altitudes, reduced atmospheric pressure means less air density, which can cause the mixture to become overly rich if not properly compensated.

The float bowl maintains a constant fuel level through a mechanical float system that opens and closes the inlet valve as needed. This system ensures that fuel is always available at the correct height relative to the jet openings, maintaining consistent fuel delivery regardless of motorcycle orientation or fuel tank level. The float bowl also incorporates venting systems that equalize pressure and prevent vacuum formation that could impede fuel flow.

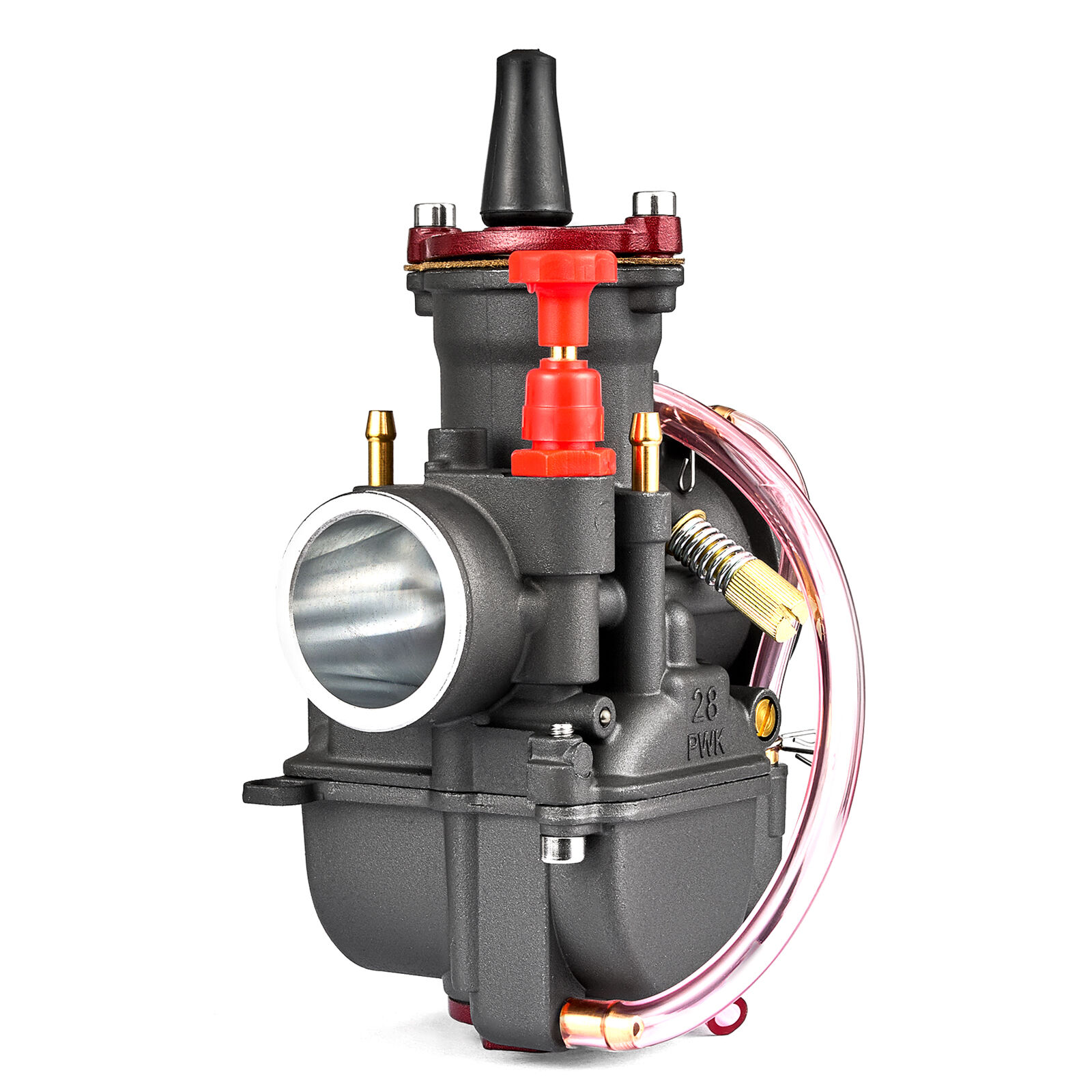

Essential Components and Their Functions

Float System and Fuel Level Control

The float system represents one of the most critical components in any motorcycle carburetor, maintaining precise fuel level control that directly impacts engine performance and fuel efficiency. The float assembly consists of a hollow brass or plastic float connected to a needle valve that regulates fuel flow from the fuel line into the float bowl. As fuel level rises, the float rises with it, gradually closing the needle valve to reduce fuel flow and maintain the predetermined fuel level.

Proper float adjustment is essential for optimal carburetor performance, as incorrect fuel levels can cause flooding, lean running conditions, or inconsistent fuel delivery. The float level determines how much suction is required to draw fuel through the jets, affecting the carburetor's responsiveness across different throttle positions. Modern motorcycle carburetors often incorporate adjustable float mechanisms that allow technicians to fine-tune fuel levels without complete disassembly.

Jet Systems and Fuel Metering

The jet system in a motorcycle carburetor consists of precisely calibrated orifices that meter fuel flow at different engine operating conditions. The main jet controls fuel delivery at wide-open throttle conditions, while the pilot jet manages fuel flow during idle and low-speed operation. These jets are manufactured to extremely tight tolerances, with orifice sizes measured in hundredths of millimeters to ensure accurate fuel metering.

Needle jets and taper needles work together to provide smooth fuel delivery during mid-range throttle operation, creating a progressive fuel curve that matches engine demands as throttle opening increases. The needle's taper profile determines fuel flow characteristics, with different taper angles and lengths providing various fuel delivery curves. This system allows the motorcycle carburetor to provide appropriate fuel enrichment as engine load and speed increase, maintaining optimal power output and fuel economy.

Throttle Response and Engine Performance

Slide and Butterfly Valve Systems

Modern motorcycle carburetors utilize either slide-type or butterfly valve throttle systems to control airflow and engine speed. Slide carburetors feature a cylindrical slide that moves vertically within the carburetor body, directly controlling both airflow and needle position for immediate throttle response. This design provides excellent throttle sensitivity and linear power delivery, making it popular for performance applications and racing motorcycles.

Butterfly valve carburetors employ a circular disc that rotates within the carburetor bore to control airflow, often incorporating constant velocity principles that automatically adjust slide position based on engine vacuum. This design provides smoother operation and better fuel economy but may sacrifice some throttle response compared to slide-type systems. The choice between these systems depends on intended application, with each offering distinct advantages for specific riding conditions and performance requirements.

Acceleration Pump and Transient Response

Many motorcycle carburetors incorporate acceleration pump systems to provide additional fuel enrichment during rapid throttle opening, compensating for the temporary lean condition that occurs when airflow increases faster than fuel delivery. The acceleration pump consists of a diaphragm or piston mechanism that injects a measured amount of fuel directly into the airflow when the throttle is opened quickly, ensuring smooth acceleration and preventing hesitation or stumbling.

The acceleration pump timing and volume must be carefully calibrated to match engine characteristics and avoid over-enrichment that could cause flooding or poor fuel economy. Modern designs often incorporate adjustable pump systems that allow tuning for different operating conditions and performance requirements. This component is particularly important in larger displacement engines where the mass of air and fuel involved makes transient response more challenging to achieve.

Tuning and Optimization Strategies

Air-Fuel Ratio Adjustment

Achieving optimal air-fuel ratios requires systematic adjustment of various motorcycle carburetor components to match engine requirements across all operating conditions. The stoichiometric ratio of approximately 14.7:1 provides complete combustion under ideal conditions, but practical applications often require slight variations to optimize power, fuel economy, or emissions. Rich mixtures provide better cooling and power at high loads, while lean mixtures improve fuel economy during light-load operation.

Tuning typically begins with pilot circuit adjustment for proper idle and low-speed operation, followed by main jet selection for wide-open throttle performance. Mid-range tuning involves needle position and taper selection to ensure smooth power delivery throughout the throttle range. Each adjustment affects multiple operating ranges, requiring iterative refinement to achieve optimal overall performance while maintaining reliability and acceptable fuel consumption.

Environmental Compensation

Environmental factors such as altitude, temperature, and humidity significantly impact motorcycle carburetor performance, often requiring adjustments to maintain optimal operation. Higher altitudes reduce air density, effectively richening the mixture and requiring leaner jetting to compensate. Temperature changes affect both air density and fuel volatility, influencing mixture requirements and carburetor response characteristics.

Cold weather operation presents particular challenges for carburetor-equipped motorcycles, as reduced fuel volatility can cause starting difficulties and poor cold-running performance. Many carburetors incorporate choke or enrichment systems that provide additional fuel during cold operation, gradually reducing enrichment as the engine warms up. Understanding these environmental effects allows riders to make appropriate adjustments or modifications for consistent performance across varying conditions.

Maintenance and Troubleshooting

Regular Service Requirements

Proper maintenance of motorcycle carburetor systems involves regular cleaning, inspection, and adjustment to ensure consistent performance and reliability. Fuel system contaminants, including dirt, water, and fuel degradation products, can clog jets and passages, causing poor performance or complete failure. Regular fuel filter replacement and periodic carburetor cleaning prevent most contamination-related problems and maintain optimal fuel flow characteristics.

Float bowl drainage and inspection should be performed regularly to remove accumulated contaminants and verify proper float operation. Worn or damaged float components can cause flooding, lean running, or inconsistent fuel delivery, requiring prompt replacement to prevent engine damage. Gasket and seal replacement during routine service prevents air leaks that can cause erratic idle and poor performance.

Common Performance Issues

Troubleshooting motorcycle carburetor problems requires systematic diagnosis to identify root causes and implement effective solutions. Common symptoms include hard starting, rough idle, poor acceleration, and excessive fuel consumption, each potentially indicating different underlying issues. Systematic testing of individual circuits and components helps isolate problems and guide repair efforts.

Vacuum leaks represent one of the most common causes of carburetor-related performance problems, causing lean running conditions that result in poor idle quality and potential engine damage. These leaks can occur at intake manifold connections, carburetor mounting surfaces, or internal gasket failures. Proper diagnosis using vacuum gauges or carburetor spray can quickly identify leak locations and guide repair efforts.

FAQ

How often should a motorcycle carburetor be cleaned and serviced

A motorcycle carburetor should typically be cleaned and serviced every 12,000 to 15,000 miles or annually, whichever comes first. However, motorcycles used infrequently or stored for extended periods may require more frequent attention due to fuel degradation and contamination. Signs that cleaning is needed include hard starting, rough idle, poor acceleration, or black smoke from the exhaust. Regular maintenance prevents most carburetor problems and ensures consistent performance.

Can altitude changes affect motorcycle carburetor performance

Yes, altitude changes significantly impact motorcycle carburetor performance due to reduced air density at higher elevations. For every 1,000 feet of altitude gain, air density decreases by approximately 3%, effectively enriching the fuel mixture. This can cause poor performance, reduced power output, and increased fuel consumption. Motorcycles regularly operated at significantly different altitudes may benefit from jetting changes or adjustable carburetor systems to compensate for these effects.

What are the signs of a worn motorcycle carburetor needle and seat

A worn motorcycle carburetor needle and seat typically causes fuel overflow, flooding, and inconsistent fuel levels in the float bowl. Symptoms include fuel leaking from the carburetor overflow tubes, engine flooding during starting attempts, and erratic performance due to varying fuel levels. The motorcycle may also exhibit rich running conditions, black exhaust smoke, and poor fuel economy. These components should be inspected and replaced during routine carburetor service to prevent performance problems.

How does temperature affect motorcycle carburetor operation

Temperature significantly affects motorcycle carburetor operation through changes in air density and fuel volatility. Cold temperatures increase air density, requiring richer mixtures for proper combustion, while reducing fuel volatility and making starting more difficult. Hot temperatures decrease air density and increase fuel volatility, potentially causing vapor lock and requiring leaner mixture adjustments. Most carburetors include cold enrichment systems to compensate for temperature effects, but extreme conditions may require manual adjustment or modification.