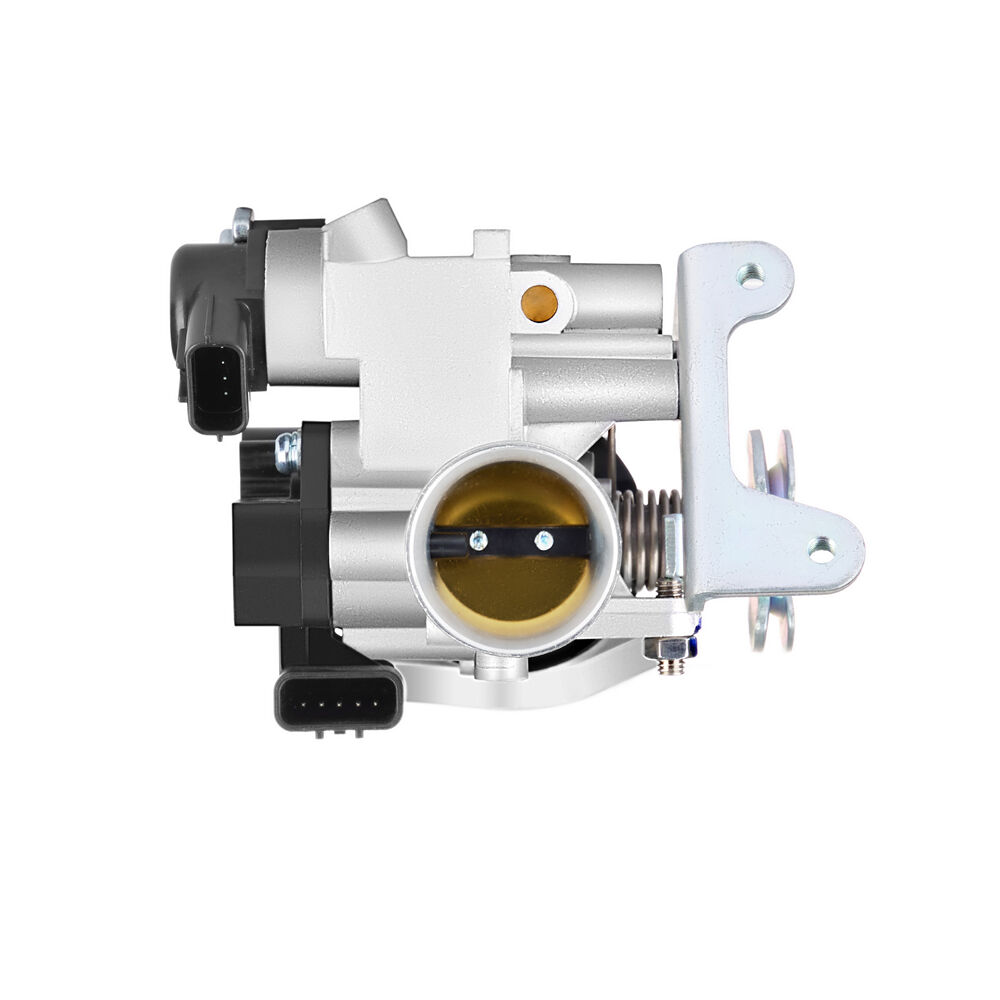

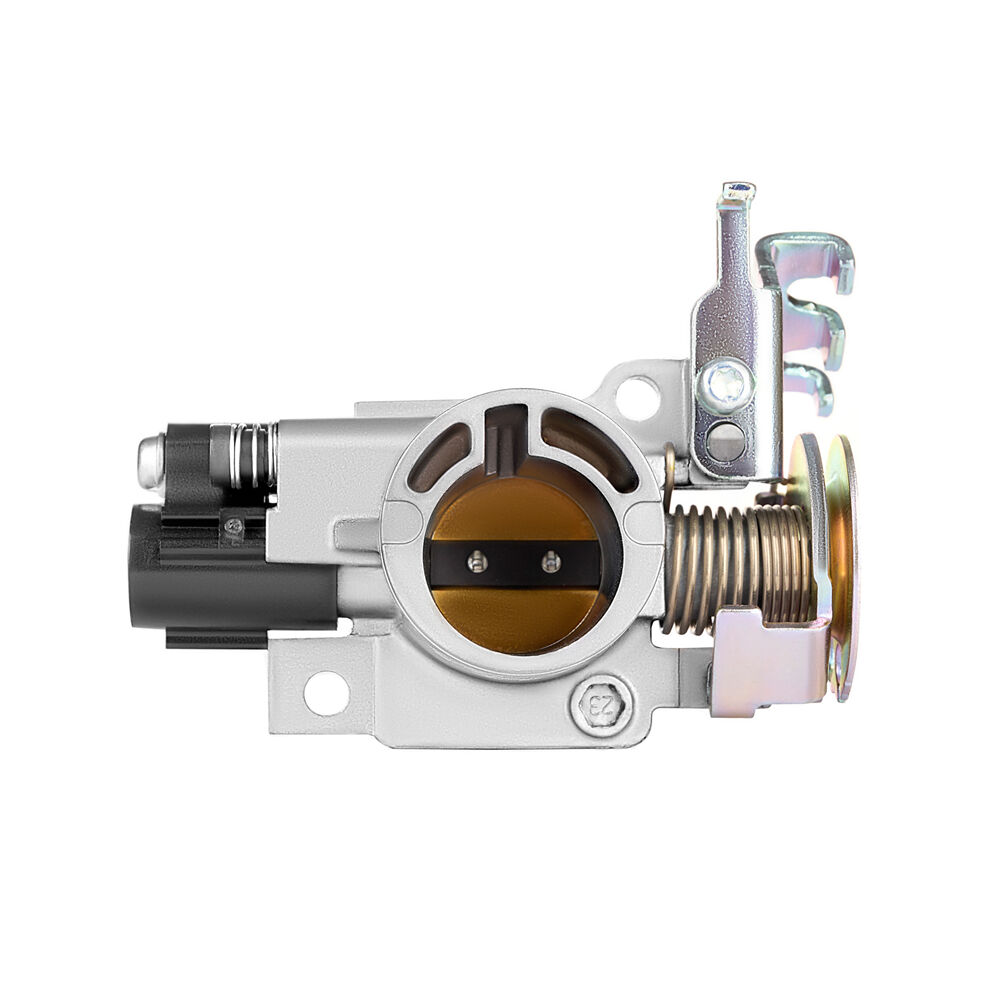

valvola a farfalla di aspirazione

La valvola a farfalla di aspirazione è un componente fondamentale nei moderni sistemi motore, progettata per regolare con precisione e affidabilità il flusso d'aria verso il motore. Questo sofisticato dispositivo agisce come meccanismo di controllo principale delle prestazioni del motore e consiste in una valvola a farfalla alloggiata nel collettore di aspirazione. Quando il conducente preme il pedale dell'acceleratore, la valvola a farfalla risponde regolando la propria posizione per consentire più o meno aria di entrare nel motore, influenzando direttamente il rapporto aria-carburante e, di conseguenza, la potenza erogata dal motore. I sistemi avanzati di controllo elettronico della valvola a farfalla, noti anche come tecnologia drive-by-wire, hanno sostituito i tradizionali collegamenti meccanici in molte vetture moderne, offrendo una precisione e una reattività migliorate. La valvola a farfalla di aspirazione integra diversi sensori e attuatori che collaborano in armonia con l'unità di controllo motore (ECU) per ottimizzare le prestazioni in diverse condizioni operative. La sua progettazione include caratteristiche come meccanismi antigelo e capacità di geometria variabile, garantendo un funzionamento costante in condizioni ambientali diverse. Oltre alla sua funzione principale di regolazione del flusso d'aria, la valvola a farfalla di aspirazione svolge un ruolo fondamentale nel controllo delle emissioni, nell'ottimizzazione dell'efficienza del carburante e nella gestione complessiva delle prestazioni del motore. La durabilità del componente è migliorata grazie a materiali di alta qualità e a processi di produzione precisi, che garantiscono un'affidabilità a lungo termine e prestazioni costanti durante l'intero ciclo di vita del veicolo.