When it comes to motorcycle safety and performance, few components are as critical as the brake disc. This essential braking system component directly impacts your ability to stop safely and control your vehicle under various riding conditions. Understanding what makes a high-quality brake disc can mean the difference between confident stops and potentially dangerous situations on the road.

Modern motorcycles rely on disc brake systems for their superior stopping power compared to traditional drum brakes. The brake disc serves as the primary contact surface where brake pads create friction to slow down or stop your motorcycle. Quality engineering and proper material selection in brake disc manufacturing directly translate to improved rider safety and enhanced performance across different riding scenarios.

Selecting the right brake disc involves understanding several key factors including material composition, design features, size specifications, and compatibility with your specific motorcycle model. These elements work together to determine overall braking effectiveness, durability, and reliability under various operating conditions.

Essential Material Characteristics for Superior Performance

Stainless Steel Construction Benefits

High-grade stainless steel represents the gold standard in brake disc manufacturing due to its exceptional resistance to corrosion and thermal stability. Stainless steel brake discs maintain consistent performance across temperature ranges while resisting the oxidation that can compromise braking effectiveness over time. This material choice ensures longevity and reliable performance even in challenging weather conditions.

The molecular structure of quality stainless steel provides optimal heat dissipation properties, preventing brake fade during intense riding sessions. Superior stainless steel grades also resist warping under extreme temperature fluctuations, maintaining the flat surface geometry essential for consistent pad contact and even wear patterns.

Carbon Steel Alternatives and Applications

Carbon steel brake discs offer excellent thermal conductivity and are often more cost-effective while still providing reliable performance for standard riding applications. These discs work particularly well for everyday commuting and moderate performance riding where extreme heat generation is less of a concern.

Modern carbon steel formulations include specific alloy additions that enhance durability and resistance to thermal stress. While requiring more maintenance than stainless steel options, quality carbon steel brake discs can deliver years of dependable service when properly cared for and regularly inspected.

Critical Design Features That Maximize Stopping Power

Ventilation and Heat Management Systems

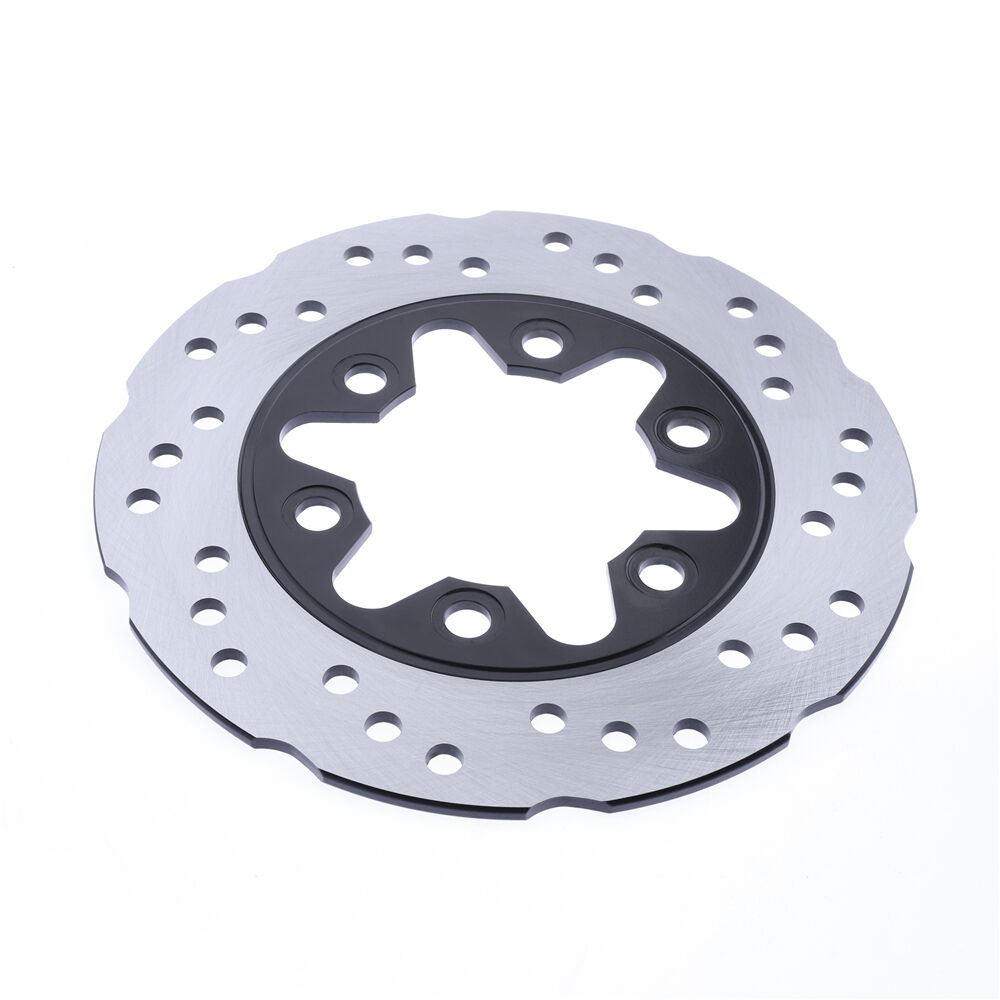

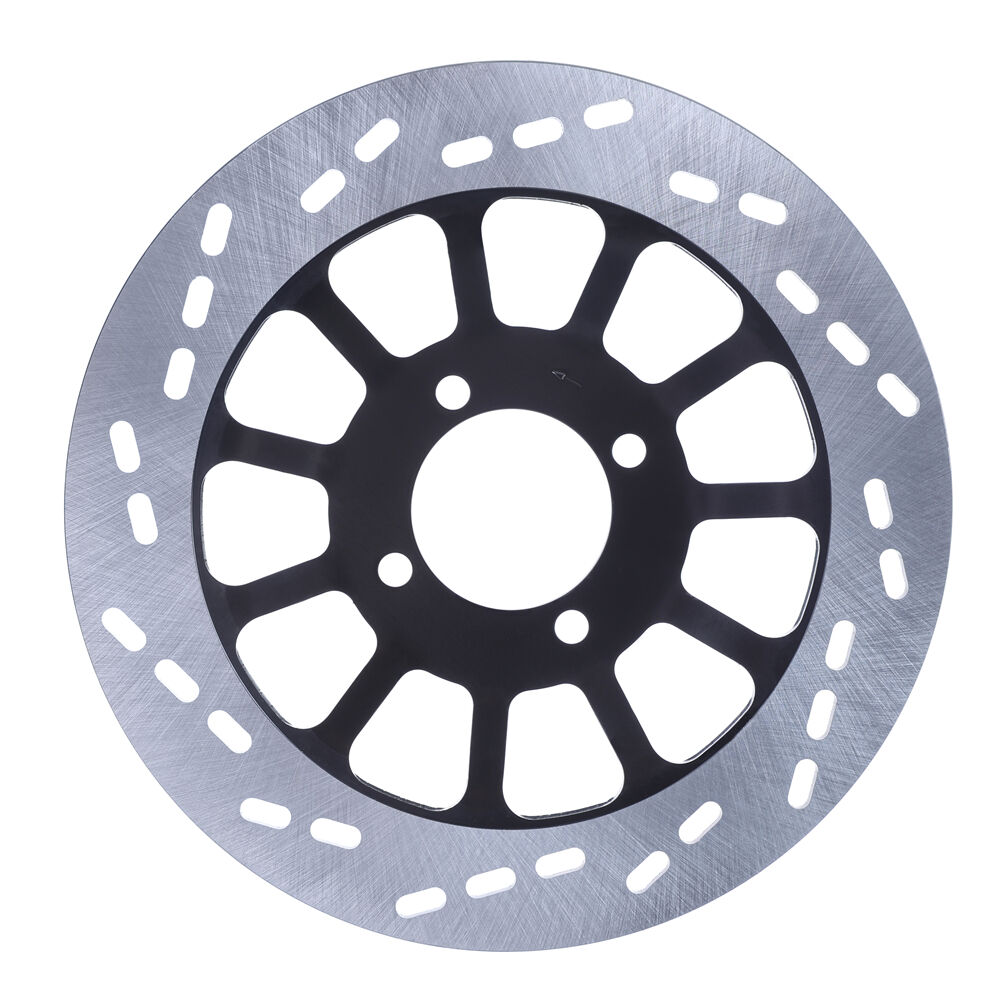

Advanced brake disc designs incorporate sophisticated ventilation patterns that promote rapid heat dissipation during braking operations. These ventilation features include strategically placed holes, slots, or curved vanes that channel airflow across the disc surface, preventing overheating and maintaining consistent friction characteristics.

Effective heat management prevents brake fade, which occurs when excessive temperatures reduce friction coefficient between pads and disc surfaces. Well-designed ventilation systems also help prevent thermal distortion that can cause vibration, uneven wear, and reduced braking efficiency over the disc's service life.

Surface Treatments and Friction Optimization

Modern brake disc manufacturing employs various surface treatments to optimize friction characteristics and extend service life. These treatments may include specialized coatings that enhance initial bite, reduce break-in time, and provide consistent friction across different temperature ranges and weather conditions.

Cross-drilling and slotting patterns serve multiple functions including debris evacuation, gas release, and heat dissipation enhancement. These features help maintain clean contact surfaces between pads and disc while preventing the buildup of brake dust and moisture that can compromise stopping performance.

Size Specifications and Compatibility Considerations

Diameter Requirements and Performance Impact

Brake disc diameter directly affects braking torque and heat capacity, with larger diameters generally providing increased stopping power and better heat dissipation. The optimal diameter depends on motorcycle weight, intended use, and caliper compatibility, requiring careful consideration of these factors during selection.

Upgrading to a larger diameter brake disc can significantly improve braking performance, but requires ensuring proper clearance with wheels, suspension components, and brake calipers. Professional installation and compatibility verification are essential when considering diameter changes from original equipment specifications.

Thickness Standards and Wear Limits

Brake disc thickness affects heat capacity, rigidity, and overall durability under braking loads. Manufacturers specify minimum thickness limits that must be maintained throughout the disc's service life to ensure safe operation and prevent catastrophic failure during emergency braking situations.

Regular thickness measurements using precision calipers help determine when replacement is necessary and prevent operation beyond safe wear limits. Maintaining proper thickness also ensures optimal pad contact and prevents excessive flexing that can cause vibration and uneven wear patterns.

Installation and Maintenance Best Practices

Proper Mounting Procedures

Correct brake disc installation requires attention to torque specifications, bolt quality, and surface preparation to ensure safe and reliable operation. Using manufacturer-specified torque values prevents over-tightening that can distort the disc or under-tightening that allows movement during braking operations.

Quality mounting hardware including bolts, washers, and thread-locking compounds must meet or exceed original equipment specifications. Proper installation also involves cleaning all mating surfaces and ensuring perfect alignment to prevent runout and vibration issues that compromise braking performance.

Ongoing Care and Inspection Requirements

Regular brake disc maintenance includes visual inspection for cracks, scoring, or excessive wear, along with measurements to verify thickness remains within safe limits. Cleaning brake disc surfaces removes accumulated debris and brake dust that can affect friction characteristics and lead to premature wear.

Professional inspection should include checking for runout, surface flatness, and proper mounting bolt torque at regular service intervals. Early detection of wear or damage allows for timely replacement before safety is compromised and prevents damage to other braking system components.

Performance Optimization and Upgrade Options

High-Performance Applications

Racing and high-performance riding applications demand brake discs with enhanced heat capacity, superior materials, and advanced design features that maintain consistent performance under extreme conditions. These specialized discs often incorporate exotic materials, advanced surface treatments, and optimized ventilation systems.

Performance brake disc upgrades can significantly improve stopping distances, reduce brake fade, and provide better feel and modulation during aggressive riding. However, these improvements often come with increased cost and may require compatible high-performance brake pads and fluid for optimal results.

Street Riding Enhancements

Street riders can benefit from brake disc upgrades that improve wet weather performance, reduce maintenance requirements, and provide enhanced durability for daily use. These improvements focus on corrosion resistance, consistent friction characteristics, and extended service life rather than maximum performance.

Upgrading to premium brake discs for street use often provides noticeable improvements in braking feel, reduced noise, and better appearance while maintaining compatibility with stock brake pads and calipers. These upgrades represent an excellent balance of performance improvement and practical benefits for everyday riding.

FAQ

How often should brake discs be replaced

Brake disc replacement intervals depend on riding style, conditions, and maintenance practices, but most discs require replacement every 20,000 to 40,000 miles. Regular thickness measurements and visual inspections help determine actual replacement needs based on wear limits and condition rather than mileage alone. Aggressive riding, frequent mountain driving, or track use accelerates wear and may require more frequent replacement.

What causes brake disc warping and how to prevent it

Brake disc warping typically results from excessive heat buildup, improper installation torque, or uneven pad contact pressure. Prevention involves avoiding prolonged heavy braking, ensuring proper installation procedures, using quality brake pads, and maintaining proper brake fluid levels. Regular inspections and adherence to manufacturer specifications help identify potential issues before warping occurs.

Can different brake disc brands be mixed on the same motorcycle

While technically possible, mixing brake disc brands is not recommended as different manufacturers may use varying materials, surface treatments, and specifications that affect braking balance and performance. Using matched brake discs ensures consistent friction characteristics, even wear patterns, and predictable braking behavior. If replacement is necessary, both discs should be replaced simultaneously for optimal safety and performance.

What are the signs that indicate brake disc replacement is needed

Key indicators for brake disc replacement include thickness below minimum specifications, visible cracks or scoring, excessive runout causing vibration, and surface irregularities that cannot be corrected through machining. Other signs include squealing noises, reduced braking effectiveness, and visible corrosion or damage that compromises structural integrity. Professional inspection can confirm replacement needs and ensure continued safe operation.